Ammonia, a route to decarbonise the global shipping industry?

Decarbonisation is the biggest challenge for the maritime industry to-date

The most recent estimates from International Maritime Organisation (IMO) show that shipping accounted for 2.89% of global CO2 emissions in 2018 and continues to grow due to an increase in global maritime trade. To put this into perspective, if shipping was represented on the world rankings for GHG emissions it would be ranked 7th. This is an inherently global industry, supporting 80% of the world’s trade by volume, and therefore the challenge of decarbonising is global. In 2018 the IMO introduced an initial strategy for the reduction of greenhouse gas (GHG) emissions from a ship, setting out a vision for the industry to reduce the carbon intensity of international shipping and a target to reduce the total annual GHG emissions by at least 50% by 2050. For those familiar with other decarbonisation targets across both industry and internationally, this target may seem conservative, especially considering the targets from countries with higher emissions. However, when it comes to the shipping industry the expected lifetime of a vessel is 30 years, meaning the ships designed today will remain part of the fleet until at least 2050. The IMO is facing pressures from regulators and other parts of the industry to strengthen the target further. The Getting to Zero Coalition, formed of over 200 organisations within the maritime, energy, infrastructure, and finance sectors, are looking to reach net zero emissions by 2050 target. To achieve this the coalition believes that commercially viable zero-emission vessels must start entering the global fleet by 2030 to make the transition to full decarbonisation possible. One of the key factors in this massive challenge is the global uptake of alternative low-carbon and zero-carbon fuels, as well as ship design and fuel flexibility.

Today the world fleet is mainly powered by diesel engines operating on marine fuel oils, however, there are an increasing number of alternative fuels coming to market including liquified natural gas (LNG) and liquefied petroleum gas (LPG). These fuels hold a very important role in the shipping industry due to their low sulphur content, enabling the industry to meet the IMO’s 2020 target reduction of 0.5% sulphur in exhaust emissions. This, however, is only a stepping stone in the wider decarbonisation strategy as it cannot possibly deliver the 50% reduction in GHG emissions by the 2050 target. More recently, low-carbon and zero-carbon fuel demonstrators are coming into operation including methanol, hydrogen, and ammonia-fuelled vessels. It is understood that the decarbonisation solution will be more diverse than the current fuel mix seen in today’s fleet, with the viability of alternative fuels varying depending on ship class, trade, and travel distance.

Ammonia as a future fuel

Ammonia is a compound made up of nitrogen and hydrogen, it has the formula NH3 and exists as a colourless, gas at room temperature and atmospheric pressure. It can be compressed and liquified at around 10 atm at room temperature, or -33°C at room pressure. Used as the basic feedstock for fertilisers for over a century, it has become one of the most produced chemicals by volume in the world due to its fundamental importance in the production of food. It was identified as an alternative fuel from as early as 1943 when it was used as a bus fuel during wartime when the availability of conventional fuels was limited. The energy storage properties of ammonia are very similar to methane (CH4) which has four carbon-hydrogen bonds that are broken to release energy. Ammonia has three nitrogen-carbon bonds that are also broken to release energy.

Although ammonia does not store as much energy as fossil fuels, it has the desirable ability to not produce any carbon-related emissions when combusted. This means that using it as a fuel in an internal combustion engine has the potential to fully decarbonise the engine. Another major benefit of ammonia is its already well-established infrastructure, with port bunkering, production facilities, and regulation in place to control handling. Currently, almost 200 harbours worldwide have ammonia terminals that serve the international trade of 20 Mt of ammonia every year. This is a key factor that places ammonia above other alternative fuels such as renewable hydrogen and synfuels.

Challenges for uptake

Ammonia is not without its challenges. Considering its chemical characteristics, it has a high autoignition temperature, meaning it is harder to combust than conventional fuels. It also suffers from a low flame speed, which can result in high levels of unburned ammonia in the exhaust of engines. In addition to unburned ammonia in the exhaust, it is also common to see significant amounts of NOx generated because of the high pressures and temperatures involved. NOx are potent greenhouse gases with a greenhouse warming potential about 265 times greater than CO2 these however can be addressed with pre-existing technologies already used in both shipping and the road transportation sector – selective catalytic reduction (SCR), which has been shown to significantly reduce the NOx emissions. When it comes to the difficulties in combustion, researchers and engine manufacturers alike are developing methods in which to improve the combustion characteristics, for example, dual fuel operation which utilises another fuel such as hydrogen to promote better combustion of ammonia.

The toxicity of ammonia poses different safety challenges than those of conventional fuels, as a result, there must be a degree of new regulation put in place around the use of ammonia-based fuels as well as technical rules for the safe design and use onboard ships. The International Code for the Construction and Equipment of Ships Carrying liquified Gases in Bulk (IGC code ) currently specifies strict requirements on the materials that can be used to store ammonia as well as on the design features intended to minimise the risks of exposing personnel to NH3 poisoning. This code also details the personal protective equipment necessary to safely manage the fuel. Although this procedure is in place for transporting ammonia via ships, the process of having that ammonia flowing onboard the ship needs to be defined. Multiple organisations such as the IMO and the Global Maritime Forum are investigating methods by which to safely carry ammonia onboard a ship and utilise it as a fuel . In addition to this, there is a wider need for research on the impact of ammonia uptake on the nitrogen cycle in general.

A final challenge that is faced with many decarbonised fuels, is associated with carbon in its production. Around 70% of ammonia production involves steam methane reformation (SMR) whilst most of the remainder involves coal gasification, alongside this the Haber-Bosch process is very energy and carbon-intensive. This results in an estimated 2.4 t CO2 per tonne of production, nearly twice as emissions-intensive as crude steel production and four times that of cement on a direct CO2 basis. For ammonia, production decarbonisation is important for the agricultural industry which is already pushing to decarbonise its processes, but also for ammonia’s success as a true zero-carbon fuel. 90% of the emissions from the production of ammonia originate from the production of hydrogen via SMR used in the Haber-Bosch Process. There are alternative proven methods for the production of hydrogen; green electrolysis utilises renewable energy to generate hydrogen from water without the need for carbon emissions.

Current Progress

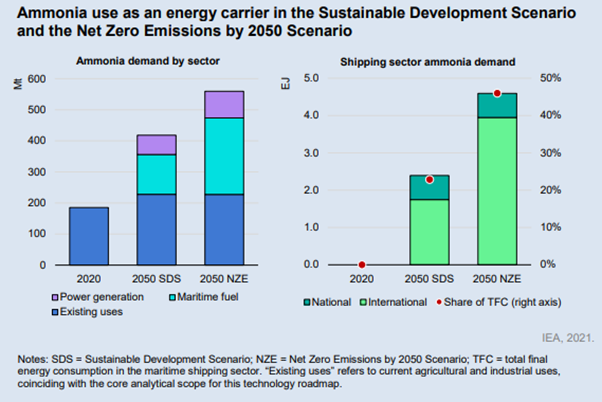

In both the Sustainable Development Scenario and Net-Zero Emissions scenario from the IEA, ammonia-fuelled maritime vessels will start to be adopted in mid-2020 with container shipping and ammonia carriers seen to be early movers due to the ability to spread the cost as well as storage capacity available on routes.

Looking at the industry, two of the world’s leading engine manufacturers, MAN-ES and Wartsila, are both developing ammonia fuelled combustion engines and are expected to make them commercially available by 2024 . Wartsila is also looking to provide a vessel retrofit for their two-stroke engines by 2025 to convert their current dual-fuel engines. This aligns with the global resurgence of maritime projects based on ammonia mapped by the Getting to Zero Coalition. Part of the Global Maritime Forum, the Getting to Zero Coalition has been mapping maritime projects since 2020, with a clear indication of an acceleration in industry activity targeting zero-emission solutions. The initial report covered 60 projects globally in 2020, with an increase to 106 in 2021 and 203 in 2022.

Market Opportunities

The international renewable energy agency (IRENA) predicted in 2021 that 70% of the shipping industry’s energy mix needs to be green hydrogen-based fuels by 2050, highlighting the pivotal role that renewable ammonia will play. Current production of ammonia reaches almost 200 Mt per year and following the predictions from the IEA in the Ammonia Technology Roadmap the demand for ammonia production is expected to double if following the Sustainable Development scenario – a predicted USD 14 billion in annual capital investment, or triple if following the Net Zero Emissions by 2050 scenario.

Another output from the Mapping of Zero Emission pilots and demonstration projects is a recognition of the high amount of public funding awarded to both hydrogen and ammonia projects, understandable considering the European Union and many other countries have identified the development of such technologies as a strategic priority. The UK’s Clean Maritime Plan released in 2019 identifies the key roles that ammonia and hydrogen will play in the decarbonisation of the UK’s shipping industry, this is mirrored globally in Japan, Australia, and many European countries.

There is no silver bullet

As with many decarbonisation challenges, the future isn’t entirely clear and there is no silver bullet to decarbonising the shipping industry. However, ammonia will play a part in the solution. There are still many hurdles for industry and researchers to overcome to ensure that ammonia is a safe and economically viable future fuel with an emphasis on support from governments, and regulations to encourage demonstrators. With many new fuel technologies, decarbonisation of the production may only come to post the increase in demand, with suppliers only willing to make these huge investments into their processes when they become economically viable. Ship owners must insist that the fuels they are turning to come from truly decarbonised production routes such as green electrolysis-derived hydrogen to make green ammonia. Otherwise, the efforts to decarbonise will only be to shift the carbon emissions up the production chain and the true effect will be negligible.

With shipbuilders, investors, and consumers becoming more aware of their own contributions to global greenhouse gas emissions, the pressure has never been higher on the shipping industry to decarbonise. Turning to alternative fuels is just one of the directions the industry must take to overcome this monumental challenge. Fuelled by the urgency of this demand, letting good be the enemy of perfect is a dangerous mindset that will lead to inaction. Ammonia may have its challenges, but the industry is willing to work to overcome these and is invested in future fuel.

Strathsquare is a seed stage project initiator that provides required resources to entrepreneurs and innovators. We are driven by a sense of urgency to transition away from unsustainable technologies and processes, we believe that what we do should have a genuinely positive impact on society and our environment.

If you have an innovative idea

We are committed to supporting innovators who have the potential to make businesses more sustainable and for all.